Greater power and flexibility for dredgers

Thanks to its adaptive platform, shipowners can completely tailor the design of the CSD Series to a desired operational profile. Some of the many options available include: self-propelled or stationary service; an anchor boom system; a barge loading system; motion compensation in the spud carrier and cutter ladder system; a Christmas tree system and a spud tilting system. The vessel is designed for renewable marine fuels such as methanol but can also run on regular marine diesel oil.

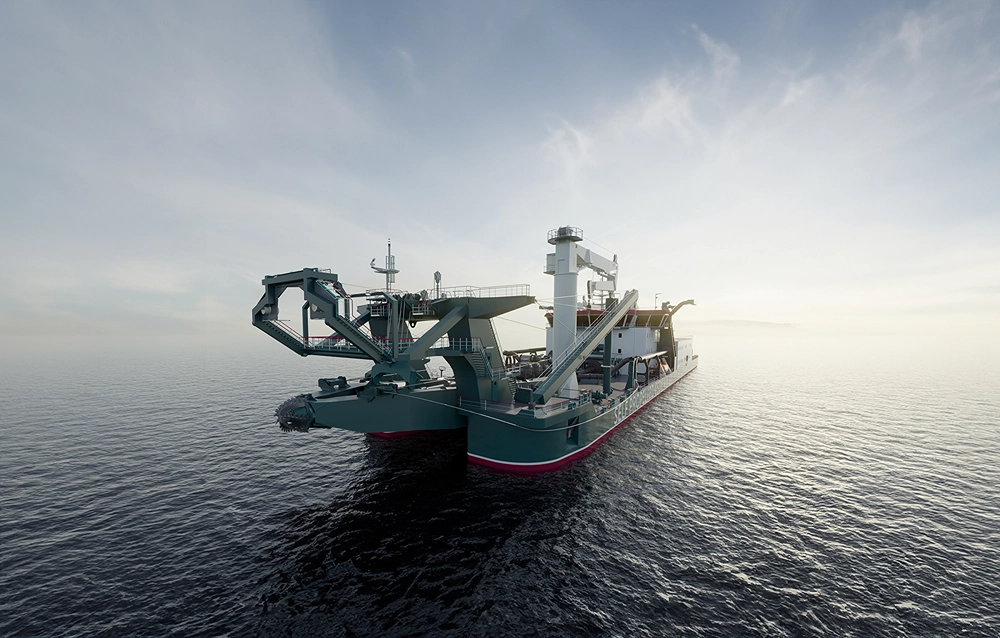

The headline vessel of the CSD Series is an innovative self-propelled cutter suction dredger of 296-feet length, which can be extended to provide an increased swing width. Operating under a US flag, the USCG-compliant vessel includes two 6,300 HP dredge pumps on deck and one submerged dredge pump to provide 34-inch cutter power of 3,500 HP. It has a total installed power of approximately 26,000 HP and the ability to dredge to depths of 95 feet.

C-Job CSD Series

Project highlights

Adaptive platform

Scalable range of design options

Multiple fuel options

Renewable marine fuels or dual-fuel propulsion

Power and size

Maximum 360′ 11″ long (110 m) with 26,000 HP total

C-Job CSD Series

C-Job specialist testimonial

C-Job CSD Series

Scope of work

Design and engineering for new-build vessels

Decarbonization, energy efficiency and compliance

Engineering works and integrations

C-Job CSD Series

Related case studies

A new CSD 30″ – for the Port of Portland